- Product description

- Technical datas

- Accesories

- Optional

Milling and drilling center FBZ-4A

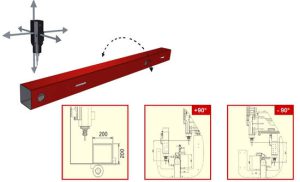

✛ 4-axis machining

✛ different angles in a clamping

✛ Operator station with PC control

✛ for working length of 3000mm

5-side editing

The FBZ-4A milling and drilling center offers 4-axis machining of aluminum profiles with a maximum cross-section of 200 x 200 mm. The automatically rotating servo work table enables interpolating machining of three sides, as well as the front faces of the profile at different angles in one clamping. The 4.0 kW spindle with SK 30 tool holder rotates at up to 18,000 rpm . Up to five pneumatic vices cover the maximum working length of 3500 mm. Lateral openings on the machine allow overlength processing (>3500mm). An automatic tool changer offers space for seven tools.

Equipment

Two machine sizes can be combined with two different milling spindles (4.0 kW and 7 kW)

Basic equipment

- Machine execution for a working length of 3000 mm (FBZ-RUMBA 3000)

- Working table +/-90° automatically tiltable via servo drive Milling spindle 4.0 kW, 18000 rpm, automatically moveable in 3 axes

- SK 30 tool holder

- Automatic tool changer with seven places

- Four pneumatic vices with two pressure levels, can be moved manually

- Left profile stop

- Protective hood with automatically opening cabin front

- Hood openings for overlength processing (>3500 mm)

- Three waste bins

- Operator station with PC control

manual function keys, PC keyboard, comfortable interface for machine parameter management, Windows operating system, automatic tool diameter correction, CNC interpolation of the X and Y axes, AXACad with CAD/CAM functions

Operating principle

The sketch illustrates the functional principle of the milling and drilling center FBZ-4A. The arrows represent the 3-axis travel of the spindle and the swivel range of the automatic servo work table.

| Art.-Nr | Type | Description |

|---|---|---|

| 8134 | FBZ- 4A | Aluminum CNC machining center Suitable for 5-sided machining, ...* |

| 8135 | RU-MSE | Micro spray device |

| 8136 | RU-SZF | Collet chuck ISO 30 |

| 8137 | RU-ZSS | Additional clamping device |

| 8138 | RU-NSA | Emergency generator 220V, 50Hz, 250VA |

| 8139 | RU-SZER25 | Collet D= 3.00-16.0mm, ER25 |

| 8140 | RU-VAR | Retractable stop (right side) |

| 8141 | RU-BCL | Barcode reader |

| 8142 | RU-GSK | Tapping compensator with drill chuck bushing |

| 8143 | RU-SPF | Spindle for milling disc |

*For further details/options see brochure

- 1x SK30 tool holder

- 1x tool Ø 8 mm

- 1x collet Ø 8 mm

- 1x spray device

- 1x maintenance unit

- 1x blow gun

- Machine version for working length of 3500mm (FBZ-RUMBA_3500)

- 7 kW milling spindle with 18,000 rpm and liquid cooling (Inox)

- Automatically positionable vices

- Additional vice (can only be moved manually)

- Barcode laser gun

- Profile stop on the right

- Tapping compensator

- Micro spray device

- Machine connection to CAL / AV programs

- Remote maintenance tool TeamViewer

Management

p.rygiel@ryko.de

Tel: (+49) 0 72 32 / 30 18-10

Mobil: (+49) 0 171 / 68 28 933