- Product description

- Technical datas

- Processings

- Optional

2-head welding machine SL2-FF-DIA

✛ Horizontal and contemporary welding

✛ Time and cost reduction

✛ It solves the problem of profile tolerances

✛ Active welding system

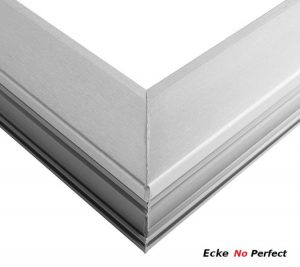

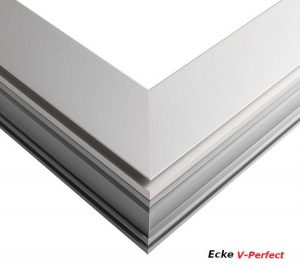

First and only 2-head CNC welding machine thatremoves the weld completely from the corner and allows you to obtain pvc windows of uniform quality and superior aesthetics.

The unique machine of this type ensures a perfect and simultaneous welding of 2 angles, guaranteeing absolutely flat and homogeneous surfaces, even with profiles that contain non-weldable products such as fiberglass, aluminum or resin instead of metal reinforcement.

Possibility of welding profiles covered with any type of film or material such as B. anodized aluminum, painted aluminum, painted Pvc, with natural wood or acrylic coated Pvc.

Time and cost reduction: No rework, cleaning, or repainting is required after welding. Therefore, the corner cleaner or a turning station are not required.

Labor Reduction: Since the corners do not need to be post-processed, only 1 operator is required to load the profiles.

Active welding system: The operator can intervene in advance on the expected final result.

It solves the problem of profile tolerances: It has a special automatic calibration system that allows you to compensate the profiles tolerances.

Welding Side Dimension (between the heads):

Welding Profile Dimensions:

Dimensions:

Details:

Performance:

Welded frames*: Up to 1/90-150 sec.

* Dependent on the types of profiles and gaskets to be processed.

Processings:

- Horizontal and contemporary welding of the 2 corners.

- Gasket worked directly during the welding cycle.

Structure:

2 Heads in line.

- Dimensions side weldable between the heads maximum increased

- Exhauster for SL2FF cordless welder.

Management

p.rygiel@ryko.de

Tel: (+49) 0 72 32 / 30 18-10

Mobil: (+49) 0 171 / 68 28 933