- SL4-FF-EVO

- Product description

- Technical datas

- Processings

After years of research and development, GRAF Synergy S.R.L. and RYKO Maschinenbau GmbH a worldwide innovation.

After years of research and development, GRAF Synergy S.R.L. and RYKO Maschinenbau GmbH a worldwide innovation.

Weld PVC window profiles without the formation of welding beads.

The new 4-head welding machine with a space requirement of only 25m² replaces a complete welding and corner cleaning line, which consists of three machines and requires an area of 85-120m². In addition to the significant space savings, other advantages are: energy savings, less maintenance work and a quality of the weld never reached before.

Numerous trade fair visitors from the window construction industry took advantage of the opportunity at the Fensterbau FRONTALE 2012 in Nuremberg at the GRAF trade fair stand. The visitors were not only able to follow the entire welding process, but also the subsequent corner fracture test and see the outstanding quality for themselves.

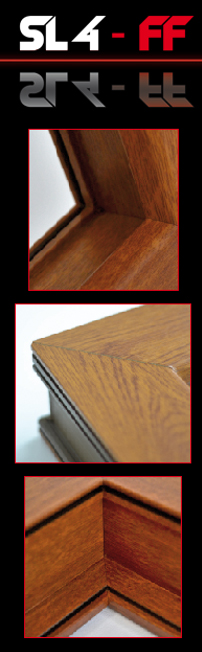

4-head welding machine SL4 FF-EVO WOOD

✛ Round shaped profile with invisible welding junction

✛ very high stability, Extreme welding precision

✛ Fully automatic CNC controls

Diese 19 CNC-Achsen gesteuerte 4-Kopf-Schweißmaschine ermöglicht das Schweißen eines kompletten PVC Rahmens in einem neuen Verfahren. Schweißen ohne nachträgliches Verputzen der Schweißraupe. Die Positionierung der Schweißköpfe erfolgt gemäß der vorgegebenen Größe des zu schweißenden Profilrahmens automatisch. Im Vorfeld findet jedoch nach dem Einlegen eine Vorarbeit statt. Um Toleranzen bezüglich Länge und Winkelgenauigkeit auszugleichen, wird eine Plan- und Konturfräsung vorgenommen. Zudem verfügt diese Maschine über ein Toleranzhöhen-messsystem, das Profilhöhendifferenzen bis 0,7mm ausgleicht. Ebenfalls automatisiert sind die Zyklen für das Beheizen, Schweißen und Abkühlen der Profilstäbe. Nach Abkühlung wird der geschweißte Rahmen mittels Transportbänder in Richtung Verputzautomat befördert.

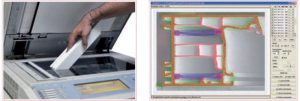

“WYSIWYG” profile programming

What You See Is What You Get.

A problem to solve on automatic conventional welders is to upload the profile drawing, shown on a computer display or on paper. For SL4 FF welder programming it’s no more necessary to use 3D CAD programs, DXF profile drawing, selfteaching procedure or complex ISO programs. It’s enough to make a photocopy or a scanning of the real profile in your hand and upload the JPEG photo file into the machine. Expert engineer assistance or machine manufacturer intervention is absolutely no more necessary for assisting a production change or insert a new profile to weld in the machine program.

Profile height tolerance compensation

In case of different profile height due extrusion tolerance, an embedded precise measuring system looks for the medium welding height automatically, compensating difference between two profile up to 0,7 mm. (well beyond normally accepted value). In case of bigger difference, machine asks the operator for confirmation to go ahead to weld.

Increasing stability of the corner by welding

Each profile has its own breaking force limit value, depending by PVC compound, profile dimension and welding process quality. New SL4 FF welder performs, with same profile type, higher breaking force compared to conventional welding-corner cleaning line.

Higher productivity

Welding process duration has been dramatically reduced. Welding time can vary between 55 and 65 sec. max , depending by profile type. Extra time to add for machine loading and unloading only. Production increase of 30% up to 200% can be obtained compared to that of conventional line.

Reduced space requirement – from 3 to 1 machine

SL4 FF no longer requires a cooling table, corner cleaner or turning station. Conventional welding and cleaning lines require between 85-120m², in some cases even more. The 4-head welding machine SL4 FF requires just 25m².

Weldable Profile Dimensions:

Weldable Side Dimensions:

Dimensions:

Details:

Performance:

Welded frames*: Up to 1/90-150 sec.

* Dependent on the types of profiles and gaskets to be processed.

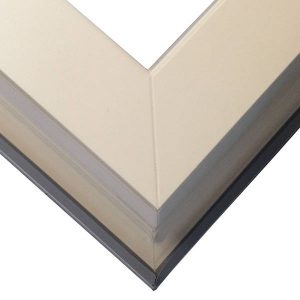

Weld bead / weld seam

Another very fundamental aspect is the quality of the weld. This process makes it possible to create a weld without subsequent plastering, and a perfect angle is also created, which sets a new standard in window production. Furthermore, the visible surface weld can be produced in 2 versions, on the one hand with a 0mm weld (invisible weld), on the other hand with a visible weld, mainly used for white profiles. Profiles with curves and invisible welds look natural and are perfect!

Management

p.rygiel@ryko.de

Tel: (+49) 0 72 32 / 30 18-10

Mobil: (+49) 0 171 / 68 28 933