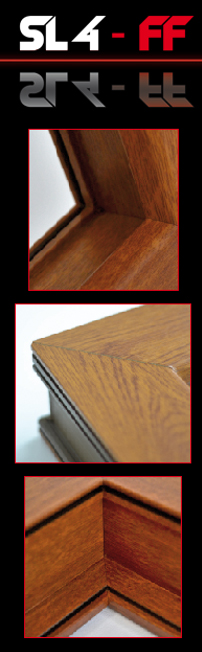

- SL4-FF-EVO

- Product description

- Technical datas

- Processings

After years of research and development, GRAF Synergy S.R.L. and RYKO Maschinenbau GmbH a global innovation.

After years of research and development, GRAF Synergy S.R.L. and RYKO Maschinenbau GmbH a global innovation.

Weld PVC window profiles without the formation of weld beads.

The new 4-head welding machine with a space requirement of only 25m² replaces a complete welding and corner cleaning line, which consists of three machines and requires an area of 85-120m². In addition to the significant space savings, other advantages are: energy savings, less maintenance work and a quality of the weld that has never been reached before.

Numerous trade fair visitors from the window construction industry took advantage of the opportunity at the Fensterbau FRONTALE 2012 in Nuremberg at the GRAF trade fair stand. The visitors were not only able to follow the entire welding process, but also the subsequent corner fracture test and see the outstanding quality for themselves.

4-head welding machine SL4-FF-EVO

✛ weld without the formation of weld beads

✛ high production rate

✛ very high stability due to special welding seam

✛ Energy savings, less maintenance work

This 19 CNC-axis controlled 4-head welding machine enables a complete PVC frame to be welded using a new process. Welding without subsequent trimming of the weld bead. The welding heads are automatically positioned according to the specified size of the profile frame to be welded. In the run-up, however, preparatory work takes place after the insertion. Face and contour milling is carried out to compensate for tolerances in terms of length and angular accuracy. In addition, this machine has a tolerance height measuring system that compensates for profile height differences of up to 0.7mm. The cycles for heating, welding and cooling the profile bars are also automated. After cooling down, the welded frame is transported towards the cleaning machine by means of conveyor belts.

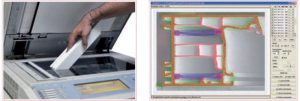

WYSIWYG Profile programming

What You See Is What You Get.

A problem with conventional automatic welding machines is the fact that you have to upload profile drawings. For the SL4 FF programming it is no longer necessary to upload or use 3D CAD programs, DXF profile drawings, profile programming PTP or complex ISO programs. A photocopy or a scan of the profile to be processed, which is uploaded to the controller as a JPEG file, is sufficient. This means that reprogramming, changing profiles, etc. is easy to do yourself and does not require the support of programming experts, etc.

Profile height tolerance compensation system

In the case of different profile heights due to extrusion tolerances, the integrated high-precision profile height measuring system intervenes automatically and communicates the tolerances. Compensation tolerances between 2 profiles up to 0.7mm. In the case of higher tolerances, the machine indicates this to the operator. The operator can continue or cancel the welding process by confirming that the tolerance has been exceeded.

VHL system (Error tolerance compensation system)

The VHL system compensates for wrong cuts of up to 2mm in length, as well as vertical/horizontal angle inaccuracies of up to 1°.

Increasing corner strength through welding

Each profile has its own corner strength value, depending on profile composition, profile dimension and weld quality. With the new SL4 FF, a significantly higher corner strength can be achieved with the same profile type compared to a conventional weld-plaster line.

Higher productivity

The processing time of the welding process could be drastically reduced. The welding time can be between 55 sec. and a maximum of 90 sec. depending on the profile type. Plus the time to load and unload the machine. Productivity increases of 30% up to 200% can be realized compared to a conventional welding and cleaning line.

Reduced space requirement – from 3 to 1 machine

SL4 FF no longer requires a cooling table, corner cleaner or turning station. Conventional welding and cleaning lines require between 85-120m², in some cases even more. The 4-head welding machine SL4 FF requires just 25m².

Dimensions of profiles that can be welded:

Dimensions of the frame that can be welded:

Dimensions:

Details:

Performance:

Welded frames*: Up to 1/90-150 sec.

* Dependent on the types of profiles and gaskets to be processed.

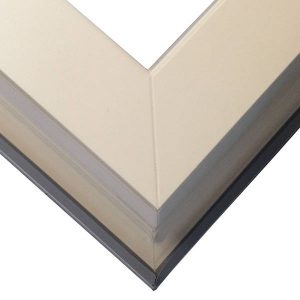

Weld bead / weld seam

Another very fundamental aspect is the quality of the weld. This process makes it possible to create a weld without subsequent plastering, and a perfect angle is also created, which sets a new standard in window production. Furthermore, the visible surface weld can be produced in 2 versions, on the one hand with a 0mm weld (invisible weld), on the other hand with a visible weld, mainly used for white profiles. Profiles with curves and invisible welds look natural and are perfect!

Management

p.rygiel@ryko.de

Tel: (+49) 0 72 32 / 30 18-10

Mobil: (+49) 0 171 / 68 28 933